Overhead Cranes

Shop Our Overhead Cranes

Get the Right Overhead Crane for the Job

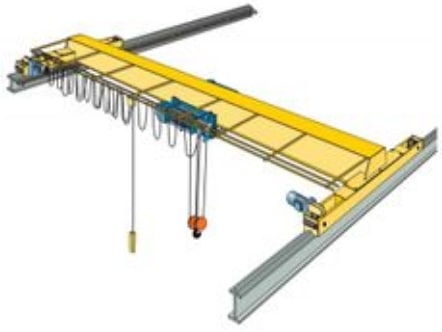

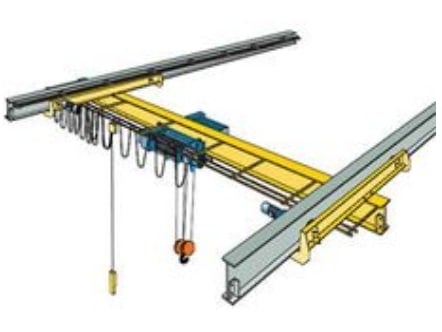

Understanding the Overhead Bridge Crane

Moving tonnage requires heavy-duty tools to ensure that the job is done safely and efficiently. The bridge crane, consisting of two overhead beams, or runways, that create a track for another perpendicular and horizontal beam, acts as both a lift and trolley for heavy materials.

Overhead Bridge Crane

While there is a difference between a gantry crane, an entirely wheeled and mobile structure, and a bridge system, the terms are often used interchangeably. These overhead systems operate with either a single or double girder system, supporting heavy loads while providing ample headroom.

Workstation Crane

Workstation cranes are often smaller than standard bridge systems but are still a versatile tool for lighter operations. This style of crane uses an enclosed track and is known for its consistency in the manufacturing industry. It also provides a full range of motion.

Overhead Bridge Crane Systems

Diving further into the specific styles of cranes, we need to discuss the variance of overhead crane parts and how these differences may alter performance. While each setup comes with a hook, hoist, runway, bridge and trolley, the specific traits of the system will affect load capacity and operation.

Top Running Cranes

A top running crane is an electronic overhead traveling crane that rides along the top of the runway beams. A typical top running system can transport or lift loads up to 35 tons with an average span of 90 feet. Obviously, there are custom setups that may allow for more versatility in design.

Under Running Cranes

Under running or underhung cranes provide a little less lift than top running systems. You can typically find these systems with a load capacity of up to 25 tons and a limited span of 75 feet. Most systems do not span more than 60 feet.

Single Girder Systems

A single girder crane is the most cost-effective option and consists of a single beam that spans the two guardrails, sitting on top or below with runway trucks. Single girder configurations hold less weight but are incredibly dependable systems, and they can be customized for your company's specific needs.

Double Girder Systems

Double girder systems are considered the workhorse models of bridge systems. These cranes consist of two bridge beams, which are typically mounted above the runway beams. If you need to lift weights of 100 plus tons, then a double girder system is what you are after.

Overhead Crane Applications

Is a bridge crane right for your business? While it is often difficult to determine the usefulness of expensive equipment, a bridge system is essential to the operations of several industries.

-

Automotive Manufacturing: One of the most obvious uses of overhead cranes is in automotive manufacturing. The constant handling of heavy components, raw materials and molds means that crane systems are essential.

-

Paper Milling: Even in businesses where a crane system seems nonessential, bridge cranes act as support. For example, the installation or maintenance of paper milling machines requires constant heavy lifting.

-

Metal Refining: The metal industry is continually operating with heavy and dangerous materials. To prevent safety hazards, overhead bridge cranes help in the handling of raw materials throughout the manufacturing process.

Hoosier Values

Productivity and Processes

We here at Hoosier Crane, understand the value of efficient work processes, and we do our best to provide systems that aid in that practice. Our overhead bridge cranes are customizable and available in a variety of configurations to suit your specific needs.